The Powerhouse and Dam were associated with the Falls Hollow Staybolt Company, a factory that manufactured wrought iron staybolts. The Falls Hollow Staybolt Company was a division of Walsh Mills that was founded by Cornelius M. Walsh, a prominent citizen and business entrepreneur in Cuyahoga Falls. Walsh Mills consisted of paper, lumber and milling companies and then later joined the staybolt industry.

Walsh Mills used a previously built timber dam north of the current powerhouse & (soon to be demolished) dam from the early twentieth century until it was destroyed by the flood of 1913. Before Walsh Mills operated the power house and dam other factories were in the same location like Loeser & Company Rolling Mill, and Loeser, Clark & Company Pearl Mills were located on the west side of the river, and the Falls Rivet Company on the east bank. Walsh appears to have taken over the property after 1900.

After the flood in March of 1913, Walsh moved the dam further downstream and constructed a new dam and powerhouse in 1914, using the ever trusty concrete to prevent future flood damage. The new dam was jointly constructed by Walsh Mills and the Falls Clutch Company, which had replaced the Falls Rivet Company, although in 1920 Walsh Mills bought out the Falls Clutch Company’s rights.

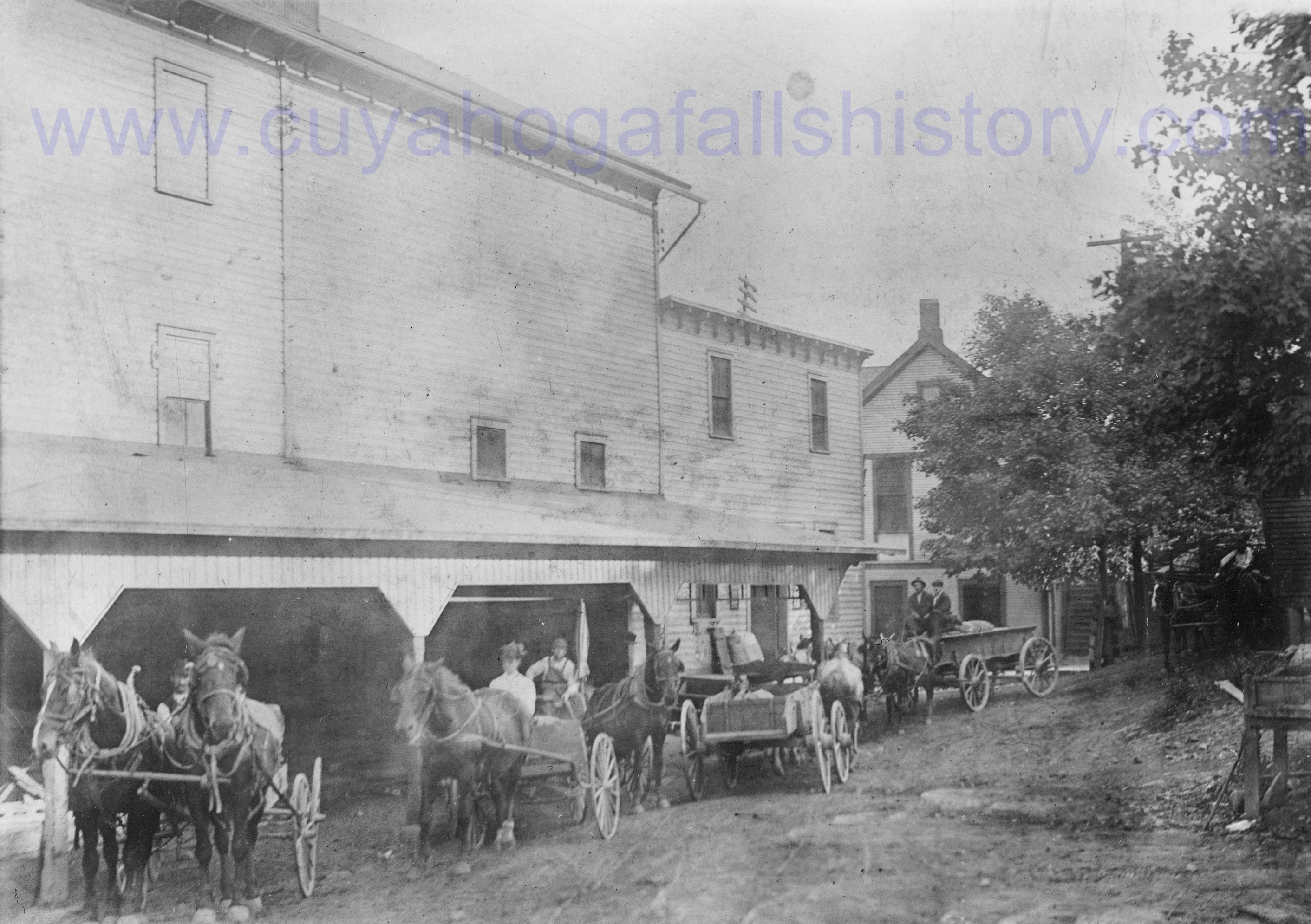

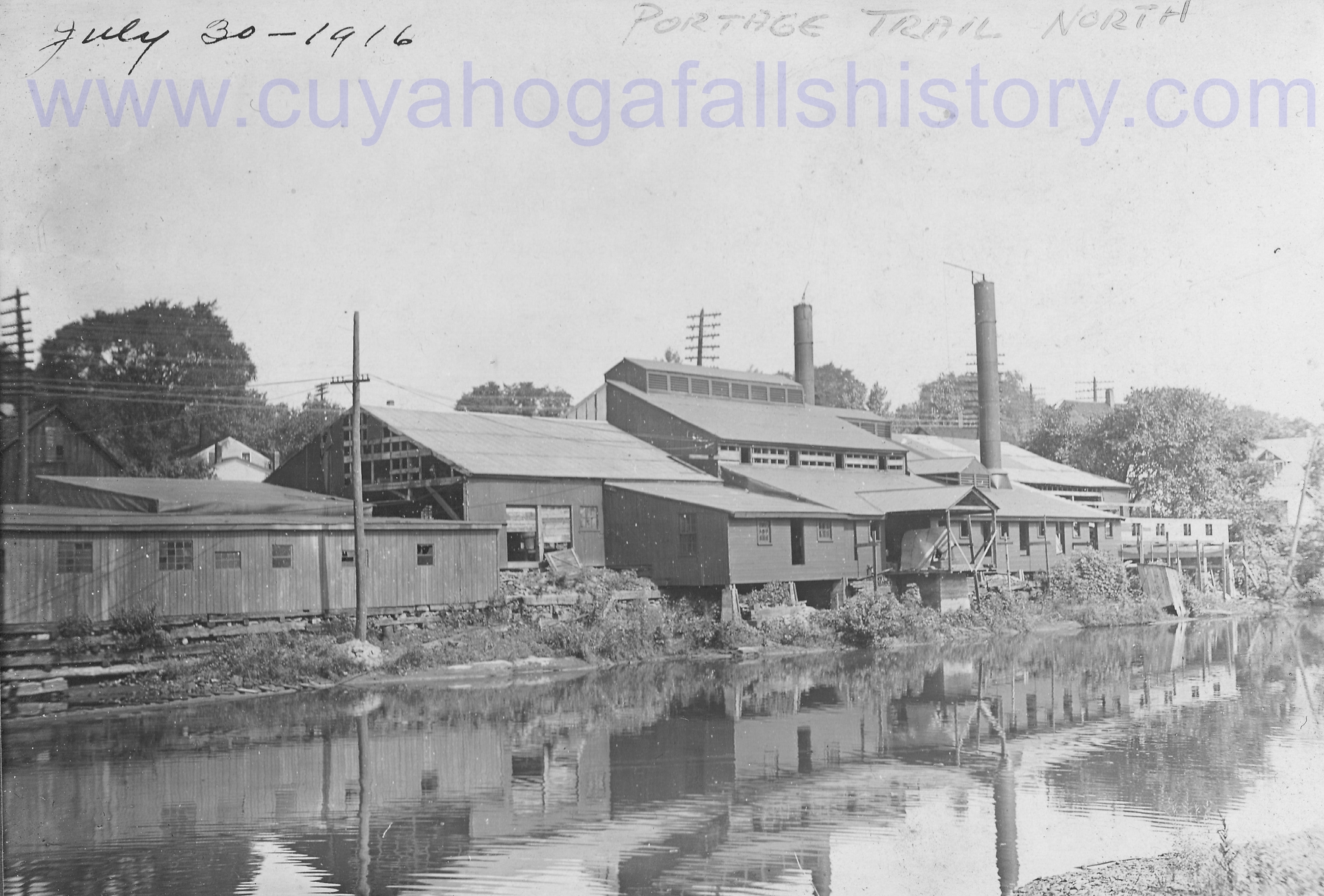

Walsh Mills in 1916

Walsh Mills in 1916

The Falls Hollow Staybolt Company was founded just after the 1913 and was the most profitable factory owned by Walsh Mills, and it required the highest amount of power. The new dam was constructed next to the factory and was the largest industrial hydroelectric plant on the river, with a 13-foot fall and two electric generators.

The dam and hydroelectric plant created electricity to drive the mill rolls in the Falls Hollow Staybolt Company plant. The mills reduced and shaped piles of wrought iron to 80-foot hollow bars that were then cut and fashioned into staybolts, which were then used to hold two sheets of steel that formed the outer shell of a locomotive firebox.

Staybolt Industries in 1916

The river provided a sufficient water flow to the factory for only a few months a year. During the summer months, the gates on the dam were closed to retain more water, since the river flow was lower during this time. Closing the gate caused issues in itself – flooding and cutting off water to other factories, such as Vaughn Machinery. The company stopped producing in 1953, and the powerhouse and most of the other Walsh Industries plants also closed around that time.

Cornelius Walsh died in 1932 without an heir, and his widow, Jane, died in 1965, and all industrial property still owned at that time by Walsh Industries was acquired by the city, for either urban renewal on the west bank of the river or for construction of the Ackerman Expressway on the east bank.

Powerhouse & Dam in 1962

*Information used from the Cuyahoga Falls Library & the city’s architecture evaluation.

I notice in your story above that you say “The Falls Hollow Staybolt Company was founded just after the 1913…”

I would like to suggest that this may be incorrect, as the following article from American Engineer and Railroad Journal, Dec-1896, p.353 shows.

“The Falls Hollow Staybolt.

Most of our readers are familiar with the staybolts made by the Falls Hollow Staybolt Company, of Cuyahoga Falls, O. The material employed in their manufacture is the best-hammered charcoal iron, and the company guarantees its product to be the equal if not the superior of any brand, domestic or imported, in the market. The Southern Railway recently tested some of these bolts… The bolts are made in all sizes from seven-eight inch to two inches outside diameter, and from one-eight inch to three-quarter inch inside diameter, depending somewhat upon the outside diameter, though considerable of a choice in the relation between the two diameters is given in the company’s list of standard sizes.”